Understanding Aluminum Case Makers: A Comprehensive Overview

In the realm of protective packaging solutions, aluminum case makers stand out for their durability, customization, and versatility. MSAcase, a leading aluminum case manufacturer, specializes in providing high-quality custom aluminum cases tailored to meet the diverse needs of industries across the globe. This article will delve into the unique advantages of aluminum cases, the customization options available, and insights into choosing the perfect case for your requirements.

The Rise of Aluminum Cases in Various Industries

Aluminum cases have garnered significant attention across various sectors, including electronics, medical, military, and more. This growing popularity can be attributed to several key factors:

- Durability: Aluminum cases are known for their robust construction, providing excellent protection against impact, weather, and dust.

- Lightweight: Despite their strength, aluminum cases are lightweight, making them easy to transport.

- Corrosion Resistance: The natural corrosion resistance of aluminum ensures that these cases maintain their appearance and functionality for years.

- Customizability: Manufacturers like MSAcase offer extensive customization options, allowing businesses to create cases that meet specific needs.

The Customization Process at MSAcase

At MSAcase, the journey from idea to finished product is streamlined and customer-focused. Here’s how the custom aluminum case creation process unfolds:

1. Initial Consultation

The first step involves a consultation where MSAcase’s experts engage with the client to understand their specific requirements, including size, shape, and intended use of the case.

2. Design Phase

After gathering all necessary information, talented designers create a prototype using advanced software, allowing clients to visualize the final product.

3. Material Selection

The choice of materials can significantly influence the case's performance. MSAcase only uses high-quality aluminum to ensure durability and longevity.

4. Production Process

Once the design is approved, the production begins with state-of-the-art machinery, ensuring precision and consistency in crafting each case.

5. Quality Assurance

Before delivery, every case goes through rigorous quality checks to ensure that it meets MSAcase's high standards as well as the client's specifications.

Key Features of MSAcase Aluminum Cases

MSAcase offers a variety of features that make their aluminum cases exceptional:

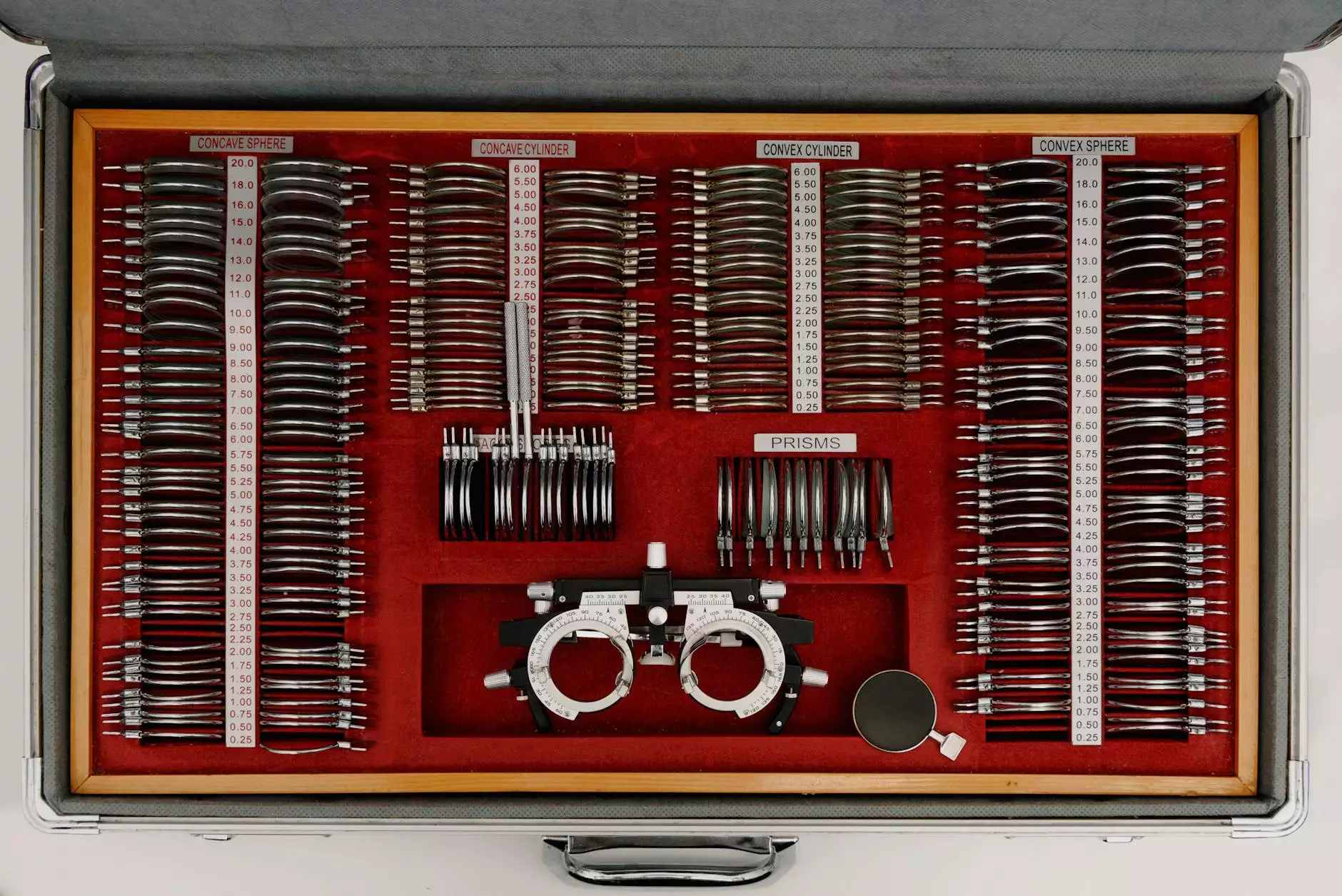

- Custom Foam Inserts: Tailored foam inserts are designed to securely hold your equipment in place, minimizing movement during transport.

- Locking Mechanisms: Various locking options add an extra layer of security, protecting valuable items from theft or inadvertent damage.

- Custom Printing: Companies can choose to have logos or branding printed on cases, enhancing company visibility and professionalism.

- Modularity: Many aluminum case designs from MSAcase are modular, allowing users to combine cases for different applications easily.

Benefits of Investing in Custom Aluminum Cases

Investing in custom aluminum cases provides numerous benefits for businesses, including:

1. Enhanced Protection

Compared to standard packaging solutions, aluminum cases provide superior protection against environmental factors and physical shocks, ensuring that valuable equipment and components arrive safely at their destination.

2. Professional Appearance

Custom aluminum cases offer a sleek and professional appearance that reflects positively on any brand, making them ideal for trade shows, client meetings, and promotional events.

3. Cost Efficiency

Although the initial investment in custom aluminum cases may be higher than other materials, the long-term savings related to damage prevention and re-purchasing of products can lead to significant cost efficiency over time.

4. Versatile Applications

From medical devices to military equipment, aluminum cases are suitable for a wide range of applications. Their modular nature allows businesses to adapt cases for various uses as needs evolve.

Choosing the Right Aluminum Case Maker

When selecting an aluminum case maker, several factors should be considered:

1. Industry Experience

Select a manufacturer like MSAcase with extensive experience in your specific industry as they will understand your unique needs and challenges.

2. Quality of Materials

Ensure that the manufacturer uses high-quality materials that meet your standards for performance and durability.

3. Customization Capabilities

Look for a company that offers comprehensive customization options to ensure you can create a case that fits your exact needs.

4. Customer Reviews

Research customer reviews and testimonials to gauge the satisfaction level of previous clients to understand the company’s reputation and reliability.

5. After-Sales Support

Select a manufacturer that values long-term relationships and provides effective after-sales support for any potential issues that may arise.

Conclusion: The Future of Aluminum Case Manufacturing

The role of aluminum case makers in the packaging industry continues to grow, driven by advancements in technology and an increasing focus on custom solutions. MSAcase remains at the forefront of this evolution, leveraging industry expertise to provide innovative case designs that cater to diverse customer needs.

With their commitment to quality, durability, and customizability, MSAcase's aluminum cases are an investment that not only protects but also showcases clients' products in the best possible light. For any business looking for aluminum case solutions, MSAcase is the go-to manufacturer to deliver superior results.